1. The assembly must be clean.

If the machine body is mixed with mechanical impurities, dust, and sludge during assembly, it will not only accelerate the wear of the parts, but also easily cause the oil circuit to be blocked, causing accidents such as burning tiles and shafts. When replacing a new injector, it is necessary to remove the anti-rust oil in the clean diesel oil at 80℃, and make a sliding test before assembling and using.

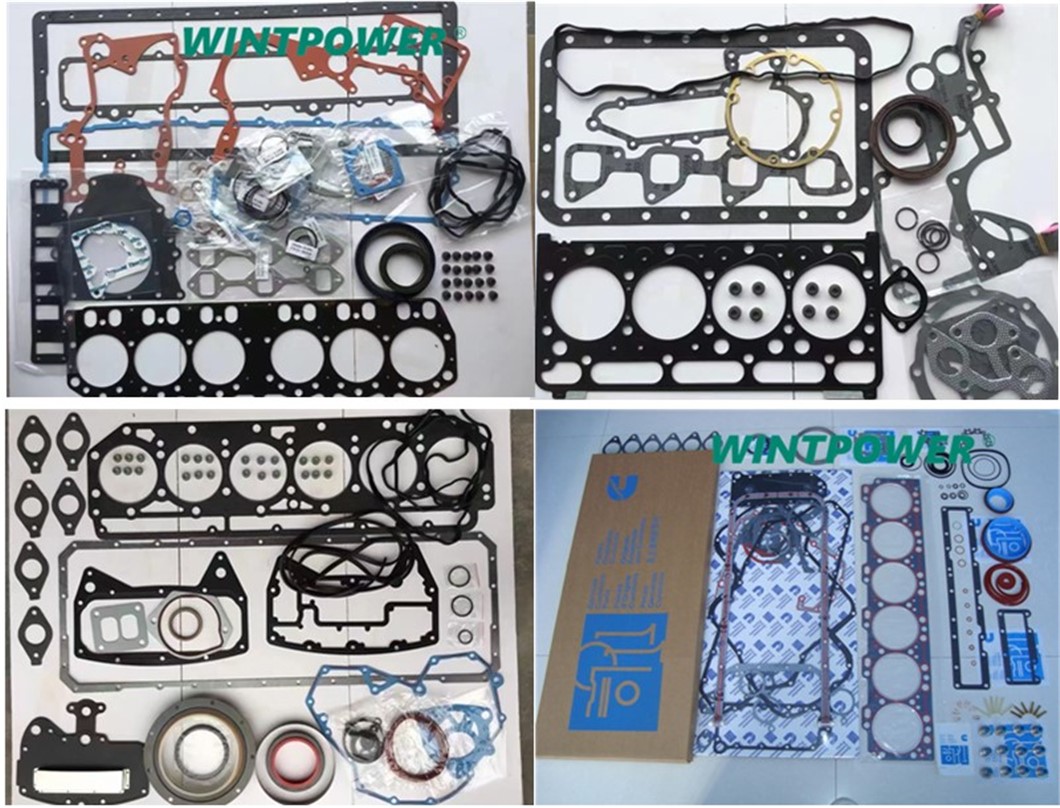

2. Pay attention to the assembly technical requirements.

Repairers generally pay more attention to valve clearance and bearing clearance, but some technical requirements are often ignored. For example, when installing a cylinder liner, the upper plane should be about 0.1 mm higher than the plane of the body, otherwise there will be cylinder leakage or continuous failure of the cylinder gasket.

3. Some matching parts need to be replaced in pairs.

The three precision parts of the injector needle valve, plunger and oil outlet valve should be replaced in pairs, which can generally be done. However, some other parts are not replaced in pairs. For example, when replacing gears, only replace the more severely worn one. After assembly, the service life will be greatly shortened as the poor meshing, increased noise and wear. When replacing the cylinder liner, the piston and piston ring should also be replaced.

4. The parts of the variant product may not be universal.

For example, the crankshaft, main bearings, cylinder liners, pistons, intake and exhaust valves, valve guides and valve springs of the diesel engine are not universal.

5. Different enlarged parts (accessories) of the same model are not universal.

When using the method of repairing size, you can choose to increase the size of the parts, but you must find out which level of the enlarged part. For example, after grinding the crankshaft for the first time, only 0.25 mm larger bearing bushes can be used. If a bearing with an increase of 0.5 mm is selected, increasing scraping of bearing bush not only wastes time, but also cannot guarantee the repair quality, and will greatly reduce the service life.

6. Prevent parts from being installed incorrectly or missing

For single-cylinder diesel engines, there are more than one thousand parts, and most of them have certain installation position and direction requirements. If you don’t pay attention, it is easy to install incorrectly or missing. If the insert position of the swirl chamber is reversed, the fuel cannot directly pass through the starting nozzle, making the engine start difficult or even can’t start at all.

Post time: Nov-30-2021