WT Natural Gas Generator Set Biogas Generator Set

WT Natural Gas Generator Set Biogas Generator Set

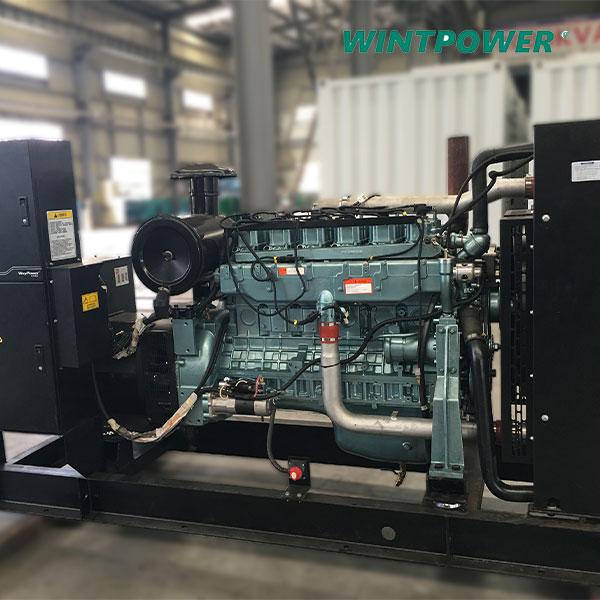

Genset Model: WTGH500-G

Continuous power: 450KW

Frequency: 50HZ

Speed: 1500RPM

Voltage: 400/230V

Fuel gas: Biogas

Genset working condition:

1. Acceptable working conditions:

Ambient temperature: -10℃~+45℃ (Antifreeze or hot water needed for below -20℃)

Relative humidity:<90%(20℃), Altitude: ≤500m.

2. Applied gas: Biogas

Acceptable fuel gas pressure: 8~20kPa, CH4 content ≥50%

Gas low heat value (LHV) ≥23MJ/Nm3. If LHV<23MJ/Nm3, gas engine power output will decrease and electrical efficiency will decrease. Gas doesn’t include free condensation water or free materials (the size of impurities should be less than 5μm.)

Relative humidity:<90%(20℃), Altitude: ≤500m.

H2S content≤ 200ppm. NH3 content≤ 50ppm. Silicon conent ≤ 5 mg/Nm3

Impurities content≤30mg/Nm3, size≤5μm, Water content≤40g/Nm3, no free water.

NOTE:

1. H2S will cause corrosion to engine components. It’s better to control it below 130ppm if possible.

2. Silicon can appear in engine lubricant oil. High silicon concentrations in the engine oil can cause heavily wear and tear on engine components. Engine oil must be assessed during CHP operation and oil type must be decided according to such oil assessment.

ComAp InteliGen NTC BaseBox is a comprehensive controller for both single and multiple gen-sets operating in standby or parallel modes. The detachable modular construction allows easy installation with the potential for many different extension modules designed to suit individual customer requirements.

InteliGen NT BaseBox can be connected with InteliVision 5 display screen which is 5.7” Color TFT display screen.

Features:

1. Support of engines with ECU (J1939, Modbus and other proprietary interfaces); alarm codes displayed in text form

2. AMF function

3. Automatic synchronizing and power control (via speed governor or ECU)

4. Base load, Import / Export

5. Peak shaving

6. Voltage and PF control (AVR)

7. Generator measurement: U, I, Hz, kW, kVAr, kVA, PF, kWh, kVAhr

8. Mains measurement: U, I, Hz, kW, kVAr, PF

9. Selectable measurement ranges for AC voltages and currents – 120 / 277 V, 0–1 / 0–5 A 1)

10. Inputs and outputs confi gurable for various customer needs

11. Bipolar binary outputs – possibility to use

12. BO as High or Low side switch

13. RS232 / RS485 interface with Modbus support;

14. Analog / GSM / ISDN / CDMA modem support;

15. SMS messages; ECU Modbus interface

16. Secondary isolated RS485 interface 1)

17. Ethernet connection (RJ45) 1)

18. USB 2.0 slave interface 1)

20. Event-based history (up to 1000 records) with

21. Customer selectable list of stored values; RTC; statistic values

22. Integrated PLC programmable functions

23. Interface to remote display unit

24. DIN-Rail mount

Integrated fixed and configurable protections

1. 3 phase integrated generator protections (U + f)

2. IDMT overcurrent + Short current protection

3. Overload protection

4. Reverse power protection

5. Instantaneous and IDMT earth fault current

6. 3 phase integrated mains protections (U + f)

7. Vector shift and ROCOF protection

8. All binary / analog inputs free configurable for various protection types: HistRecOnly / Alarm Only

9. / Alarm + History indication / Warning / Off load /

10. Slow stop / Breaker Open&Cool down / Shutdown

11. Shutdown override / Mains protect / Sensor fail

12. Phase rotation and phase sequence protection

13. Additional 160 programmable protections configurable for any measured value to create customer-specific protections

| WINTPOWER-Cummins biogas engine | Gas Engine |

| Brushless, Self-excited, Leroy Somer alternator | Alternator |

| ComAp IG-NTC-BB controller, with synchronization panel | Control system |

| Plate heat exchanger for jacket water and remote radiator for intercooler | Cooling system |

| Gas hand valve | Gas train |

| Solenoid valve from Italy | |

| Gas flame | |

| Zero Pressure valve | |

| HUEGLI gas mixer with MOTORTEC actuator (automatic AFR) | Mixing system |

| ALTRONIC ignition controller and MOTORTECH ignition coils | Ignition system |

| Batteries, battery charger, elbow, silencers and so on. | Genset accessories |

| Engine parts books, Generator set maintenance and operation manual | Documents |

| Alternator maintenance and operation manual | |

| Controller maintenance and operation manual | |

| Electrical drawings and installation drawings. |

Model KD500-SPSynchronization Panel

Capacity 1000A

Air circuit breaker brand ABB

Controller ComAp IG-NTC-BB

Features:

1. Automatically parallel the gen-set

2. Automatically unload the gen-set

3. Programmed start and stop gen-set

4. Gen-set monitoring and protecting

5. synchronize gensets with national grid(mains)

d. 2x500kW gas generators in Colombia oil field, installed in May of 2012.Some of our gas generators reference projects

a.2x500kW gas generators in Nigeria, installed in October of 2012.

b.2x500kW gas generators in Russia, installed in December of 2011.

c. 2x250kW gas generators in England, installed in May of 2011.

| WINTPOWER biogas genset data | |

| Genset model | WTGS500-G |

| Standby power (kW/kVA) | 500/625 |

| Continues power (kW/kVA) | 450/563 |

| Connection type | 3 phases 4 wires |

| Power factor cosfi | 0.8 lagging |

| Voltage(V) | 400/230 |

| Frequency (Hz) | 50 |

| Rated current(Amps) | 812 |

| Gas genset electrical efficiency | 36% |

| Voltage Stabilized regulation | ≤±1.5% |

| Voltage Instantaneous regulation | ≤±20% |

| Voltage Recovery time (s) | ≤1 |

| Voltage Fluctuation ratio | ≤1% |

| Voltage Wave aberration ratio | ≤5% |

| Frequency Stabilized regulation | ≤1%(adjustable) |

| Frequency Instantaneous regulation | -10%~12% |

| Frequency Fluctuation ratio | ≤1% |

| Net weight(kg) | 6080 |

| Genset dimension(mm) | 4500*2010*2480 |

| WINTPOWER-Cummins Biogas Engine Data | |

| Model | HGKT38 |

| Brand | WINTPOWER-CUMMINS |

| Type | 4 stroke, water-cooling, wet cylinder liner, electronic-control ignition system, pre-mixed perfect mixed burning |

| Engine output | 536kW |

| Cylinders& Arrangement | 12, V type |

| Bore X Stroke(mm) | 159X159 |

| Displacement(L) | 37.8 |

| Compression ratio | 11.5:1 |

| Speed | 1500RPM |

| Aspiration | Turbocharged & intercooled |

| Cooling Method | Water cooled by fan radiator |

| Carburetor/gas mixer | Huegli gas mixer from Switzerland |

| Air/fuel mixing | Automatic air/fuel ratio control |

| Ignition controller | Altronic CD1 unit |

| Firing order | R1-L6-R6-L1-R5-L2-R2-L5-R3-L4-R4-L3 |

| Governor type(speed regulating type) | Electronic governing, Huegli Tech |

| butterfly valve | MOTORTECH |

| Starting method | Electric, 24 V motor |

| Idling speed(r/min) | 700 |

| Biogas consumption(m3/kWh) | 0.46 |

| Oil recommended | SAE 15W-40 CF4 or above |

| Oil consumption | ≤0.6g/kW.h |

| Alternator Data | |

| Brand | WINT |

| Model | SMF355D |

| Continuous power | 488kW/610kVA |

| Rated Voltage (V) | 400/230V / 3 phase, 4 wires |

| Type | 3 phase/4 wire, brushless, self-excited, drip proof, protected type. |

| Frequency (Hz) | 50 |

| Efficiency | 95% |

| Voltage regulation | ± 1 %(adjustable) |

| Insulation class | Class H |

| Protection class | IP 23 |

| cooling method | wind-cooling, self-heat-rejection |

| Voltage regulating mode | Automatic voltage regulator AS440 |

| Compliant with international standards: | IEC 60034-1, NEMA MG1.22, ISO 8528/3, CSA, UL 1446, UL 1004B on request, marine regulations, etc. |

Products categories

-

Phone

-

E-mail

-

whatsapp

whatsapp

-

WeChat

-

Top